Carrier Bags

Carrier bags are usually manufactured from polythene but can also be made from alternative eco-friendly materials such as potato starch. Carrier bags are most commonly produced for shops, stores and supermarkets to give to their customers and so are the best known type of 'Retail Bag'.

Retail bags are produced in different styles and sizes, with a gusseted size or a flexi-loop and many other options. However the vest-style carrier bag is probably the most traditional type as they are economic and strong.

Results from recent searches on carrier bags

Shopping bags

I, like any other girl, like also walk around swinging my shopping bags after I’ve purchased a gorgeous part of clothing or accessory. But this bag below, has me thinking twice before I walk out of a store brandishing my shopping bag for all to see .

APPARATUS FOR THE DISTRIBUTION OF CARDS ON PAPER CARRIERS AND RELATED ENVELOPING APPARATUS

Paper carrier bags let your emblem and client shine

We can assist you create new packaging, or optimise your current paper carrier bags and consumer bags. Our expertise and Bag Lab services spectrum from insights in packaging trends and innovations, which we readily share with you, to scientific tests and analyses giving you a truly competitive advantage.

After offering Aircraft Carriers and 6th Gen Fighters, UK now offers ‘Electric Propulsion’ to United Kingdom

At a discussion on United Kingdom-UK cooperation in IOR organised jointly by the British High Commission and the Vivekananda International Foundation, according to the Admiral both sides can work together and there are several opportunities which would further deepen cooperation between the two. Adding, also, areas like safety and the electric propulsion on the aircraft carriers can be explored.

Also, the regulations require persons intending to import, export, manufacture or sell plastic carrier bags after June 1, 2019 to register for a licence or enable.

Plastic Vest Style Carrier Bags Small Supermarket Jumbo Size Mix Colour/MixSise

Plastic Vest Style Carrier Bags Small Supermarket Jumbo Size Mix Colour/MixSise

For example, lignin is being transformed into non-toxic polymer membranes. This naturally-sourced material could be used to make pill casings and capsule coatings for medical, pharmaceutical and nutritional applications, as well as in agriculture as fully biodegradable carriers for the progressive and controlled release of bio-pesticides and fertilisers.

REAL Digital invented 650mm wide, high quality, colour duplex web inkjet printing by mounting a pair of singlepass inkjet presses on a flexible transport system. And they developed new paper coatings to achieve the quality demanded by leading emblems for personalised carriers, mailers and magazines.

Leading Supplier of Printed Carrier Bags

We work with all type of business and in all industry. We meet the requirements of big multi-national companies only as well as we do the sole trader and all small, medium and big scale organizations wanting printed carrier bags for a promotion or exhibition.

Any commercial use of the photos which authours we are, and also their use in printing editions and on other printed carriers is strictly forbidden without our written consent.

Clear plastic carrier bags

Clear plastic carrier bags are made from strong varigauge film. Varigauge because they are thicker around the handles to give extra resistance and thinner toward the bottom. Clear poly bags are completely see-through meaning customers can see what is inside clearly. This type of carriers can comfortably hold up to 5kg.

Heavy Duty Carrier Bags

Heavy duty carrier bags are suitable for multi-uses including food, use small plastic bags to packing food and large plastic bags to protect your items or pack heavy items. Lightweight and durable these heavy duty poly bags are available in many sizes and models.

Printed Carrier Bags

Printed carrier bags offer an economic and effective marketing solution. Printing a logo or a website address on a shopping bag can help getting the name of your company on the market for a low cost. Customer that by from you will carry the bag wherever they go allowing for other people to see and chances are big that they will come to your shop.

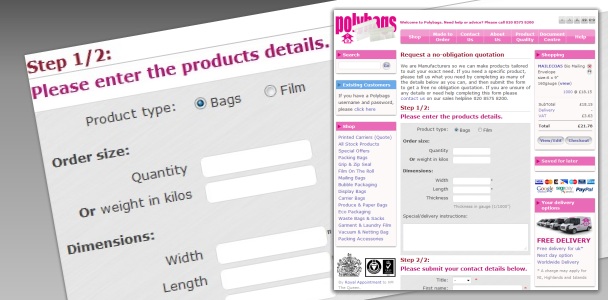

Polybags is the UK leading manufacturer and supplier of polythene packaging and they also offer custom printing services, so if you need to promote you company by having your brand printed make sure to visit Polybags and just fill a printed carrier bags form with your request.

Biodegradable Carrier bags

Having your logo or message printed on retail bags is one way to get to your customers but another great idea is to provide environmentally friendly carriers and your customers will notice that you are concerned with the environment and will give you more credit. Biodegradable carrier bags will break down when disposed of with industrial compost. Biodegradable bags can also be manufactured from potato starch which is 100% renewable and sustainable and will completely disintegrate into CO2, water and biomass in about 12 weeks if disposed in standard composting conditions.

Paper Carrier Bags

For smart alternative to traditional polythene carrier bags, paper bags could be a great solution. Paper carrier bags are strong, smart and biodegradable and they are generally made from materials like kraft, duplex and art card.

Eco-friendly, recyclable and resistant, paper carriers can be used for food packaging, the well known 'take away' bag, as well as a shopping bag. Paper bags can also be ordered with customized printing and with different handle designs, styles and colours.